The Liquid Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids. It is specially designed to take care of two critical factors which directly affect the quality of the liquids with minimum manual handling of liquid.

A filter press is a piece of equipment used in liquid/solid separation. Specifically, the filter press separates the liquids and solids using pressure filtration, wherein slurry is pumped into the filter press and is dewatered under pressure. Basically, each fitter press is designed based on the volume type of slurry that needs to be dewatered. Mechwell is a trusted expert in liquid/solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering.

| TYPES | DIAMETER OF PLATE | NO. OF PLATES | FILTERING AREA M2 | CAKE HOLDING CAPACITY (LTRS) | CAPACITY (LTR/HR) |

|---|---|---|---|---|---|

| MW-8x6 | 8” | 6 | 0.198 | 4.50 | 400 |

| MW-8x8 | 8” | 8 | 0.254 | 5.78 | 500 |

| MW-14x8 | 14” | 8 | 0.756 | 27.00 | 1500 |

| MW-14x10 | 14” | 10 | 0.924 | 35.00 | 1800 |

| MW-18x8 | 18”D | 8 | 1.270 | 51.00 | 2500 |

| MW-18x15 | 18”S | 15 | 2.270 | 44.00 | 4500 |

| MW-18x12 | 18”D | 12 | 1.840 | 78.00 | 3700 |

| MW-18x23 | 18”S | 23 | 3.400 | 65.00 | 6800 |

| MW-24x12 | 24”D | 12 | 3.430 | 148.00 | 6700 |

| MW-24x23 | 24”S | 23 | 6.336 | 12.00 | 12600 |

| MW-24x23 | 24”S | 23 | 6.336 | 12.00 | 12600 |

The Mechwell Rapid Mixer Granulator ideal mixer is widely used in pharmaceutical, chemicals and food industry for wet granulation, dry mixing, and wax granulation along with aqueous and solvent granulation. The Skyline RMG is so design to achieve efficient, sate and hygienic mixing by reducing processing time, homogeneous mixing, even distribution of binder, wetting, nucleation and granule size growth with sampling provision for in process analysis and proven safety during processing, complaint to CGMP norms.

| MODEL (SKY) | RMG -60 | RMG -100 | RMG -150 | RMG -200 | RMG -250 | RMG -400 | RMG -600 | RMG -800 | RMG -1000 | RMG -1200 |

|---|---|---|---|---|---|---|---|---|---|---|

| Goss Capacity (In Ltrs) | 60 | 100 | 150 | 200 | 250 | 400 | 600 | 800 | 1000 | 1200 |

| Working Capacity (In Ltrs.) | 48 | 80 | 120 | 160 | 200 | 320 | 480 | 640 | 800 | 960 |

| Working Capacity (in Kgs.)0.5BD | 15-20 | 25-35 | 40-55 | 55-80 | 65-90 | 100-140 | 150-215 | 200-280 | 250-350 | 250-350 |

| Impeller Motor HP/kW | 5/3.7 | 10/7.5 | 15/11.2 | 20/15 | 20/15 | 40/30 | 50/37.5 | 60/45 | 60/45 | 75/56 |

| Chopper Motor- HP/kW | 2/1.5 | 3/2.2 | 5/3.7 | 5/3.7 | 5/3.7 | 7.5/5.6 | 7.5/5.6 | 7.5/10 | 10/7.5 | 10/7.5 |

| MODELS | RMG -1 | RMG -2 | RMG -3 | RMG -4 | RMG -5 |

|---|---|---|---|---|---|

| Gross Capacity (In Ltrs) | 1 | 2 | 3 | 5 | 10 |

| Working Capacity (In Ltrs) | 0.8 | 1.6 | 2.4 | 4 | 8 |

| Working Capacity 0.5 BD | 0.15-0.4kg | 0.3-0.8kg | 0.45-1.2kg | 0.75-2kg | 1.5-4kg |

| Impeller Motor HP/kW | 0.5/0.37 | 1-0.75 | 1/0.75 | 2/1.5 | 3/2.25 |

| Chopper Motor HP/kW | 0.5/0.37 | 0.5/0.37 | 0.5/0.37 | 0.5/0.37 | 1/0.75 |

Mechwell Binder Preparation Vessel (Paste Preparation Kettle) has been designed uniquely for optimal mixing efficiency so as to ensure a homogeneous mix.The special in the vessel has been designed to create vortex inside the solvent which enhances the desired solubility of pharmaceutical binder solute into the various solvents. Due to its unique design the binder solution can be directly transferred into the processing equipment such as high shear mixer granulator, planetary mixers or fluid bed processor.

The Tilting paste kettle is designed for preparation. It has a universal application resulting in uniform melting. This tank is designed to meet missing needs of wider range of products under varied operating conditions in chemicals, foods, cosmetics and pharmaceutical industry. The basic principle utilized in the design of this kettle is the jacket for passing steam in order to melt down the product to make paste. This kettle has a unique tilting arrangement for discharging the product. The Starch Paste Kettle confirms to CGMP norms and comprises of a jacketed hemispherical bowl with all necessary steam accessories.

Fluidized bed dryer (also called fluid bed dryer) is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. The equipment works on a principle of fluidization of the feed materials. In fluidization process, hot air is introduced at high pressure through a perforated bed of moist solid particulate. The wet solids are lifted from the bottom and suspended in a stream of air (fluidized state). Heat transfer is accomplished by direct contact between the wet solid and hot gases. The vaporized liquid is carried away by the drying gasses. Sometimes to save energy, the exit gas is partially recycled.

| MODEL | FBD 3D | FBD 6D | FBD 12D | FBD 20D | FBD 25D | FBD 30D | FBD 50D |

|---|---|---|---|---|---|---|---|

| Container Gross Volume (Ltr.) | 100 | 200 | 400 | 670 | 800 | 1000 | 1650 |

| Batch Capacity-Kgs. | 30 | 60 | 120 | 200 | 250 | 300 | 500 |

| Drying Temp in oC | - | - | - | 50-85 | - | - | - |

| Electric Load in kW | 18 | 36 | 54 | - | 103400 | - | - |

| Steam supply 3 kg/cm2 in Kcal/hr | 12925 | 25850 | 51700 | 82720 | 6000 | 129250 | 196460 |

| Blower Capacity m3/hr | 2000 | 2500 | 3000 | 6000 | 25 | 12500 | 16500 |

| Elec. Motor HP | 15 | 15 | 20 | 30 | - | 30 | 40 |

To Industries where 100% pure pyrogen-free water injection plays role, Multicolumn Distillation Plant is the perfect Multicolumn Distillation Plant Solution. Available in capacities ranging from 80-5000LPH, the Multicolumn Distillation Plant is used for its economy, low maintenance and low operation costs. Manufactured from high-grade raw material and have a capacity of 50 to 2500 ltrs.

A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsions. Colloid mills work on the rotor-stator principle: a rotor turns at high speeds (2000 - 18000 RPM). The resulting high levels of hydraulic shear applied to the process liquid disrupt structures in the fluid. Colloid mills are frequently used to increase the stability of suspensions and emulsions, but can also be used to reduce the particle size of solids in suspensions. Higher shear rates lead to smaller droplets, down to approximately 1 µm which are more resistant to emulsion separation.

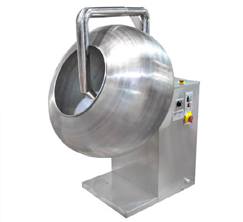

The pan is slightly tilted to an angle about 45oC to the bench top. The standard coating pan has an electric motor that rotates the circular metal pan horizontally to its axis. It is the motion of this pan that causes a batch of tablets to tumble. Again the conventional pan system has inlet air supply.

| MODEL | 12” | 18” | 24” | 30” | 36” | 42” | 48” | 56” | 72” |

|---|---|---|---|---|---|---|---|---|---|

| Loading Capacity in Kg. | 05 | 7 to 8 | 20 to 25 | 40 to 45 | 60 to 80 | 90 to 100 | 110 to 120 | 150 to 210 | 200 to 250 |

| Motor HP | 0.5 | 0.5 | 1.0 | 1.5 | 1.5 | 2.0 | 2.0 | 5.0 | 7.5 |

| Blower HP | 0.25 | 0.25 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 2.0 | 2.0 |

| Blower fan Volume CFM | 90 | 90 | 150 | 150 | 150 | 150 | 150 | 300 | 300 |

| Heater Capacity in kW | 1.0 | 1.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 5.0 | 5.0 |

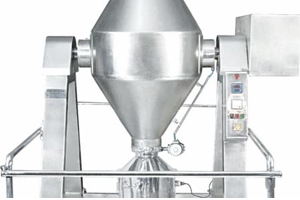

Conta Blending system has replaced completely the conventional blenders like ‘V’ shape / double cone or Ribbon type.

It is a latest CGMP concept with an emphasis on the dust free transfer of powders and granules at different stages from

sizing / dispensing to compression/ tiling of Tablets or Capsules.

Conta Blender has a flexibility of batch volume. Varying size of containers can be mounted on a drive console which

is equipped which clamping cage. Batch size variation achievable in 500Kg.

Model for example is from 75 Kg to 500Kg using two different sizes of containers.

The mixing efficiency is better than the other type of tumbling blenders like Double Cone,

'V' or Octa as they rotate in a diagonal and in a eccentric plane.

It shuffles the product intimately resulting in homogeneous blend within 5- 20 min.

The V Cone blender with its V cone shaped bin ensures efficient blending suitable for specified user's requirement. The cone is statically balanced to avoid any excessive load on the gearbox and motor.

Conical shape enables uniform mixing and easy discharge.

| TYPES | KVCB 50 | KVCB 100 | KVCB 300 | KVCB 600 | KVCB 1000 | KVCB 1500 |

|---|---|---|---|---|---|---|

| Capacity (In Ltrs) | 50 | 100 | 300 | 600 | 100 | 1500 |

Planetary Mixer is used in various applications such as Ointments, Pharmaceutical Creams, Cosmetic Creams, Ceramics, Ink Pastes, Colour Pigments, Rubber, Compounds etc. Planetary Mixer is useful for thorough mixing of ointment, creams, lotions, toothpastes etc. in sterile or non-sterile conditions.